一、塑膠射出是什麼?

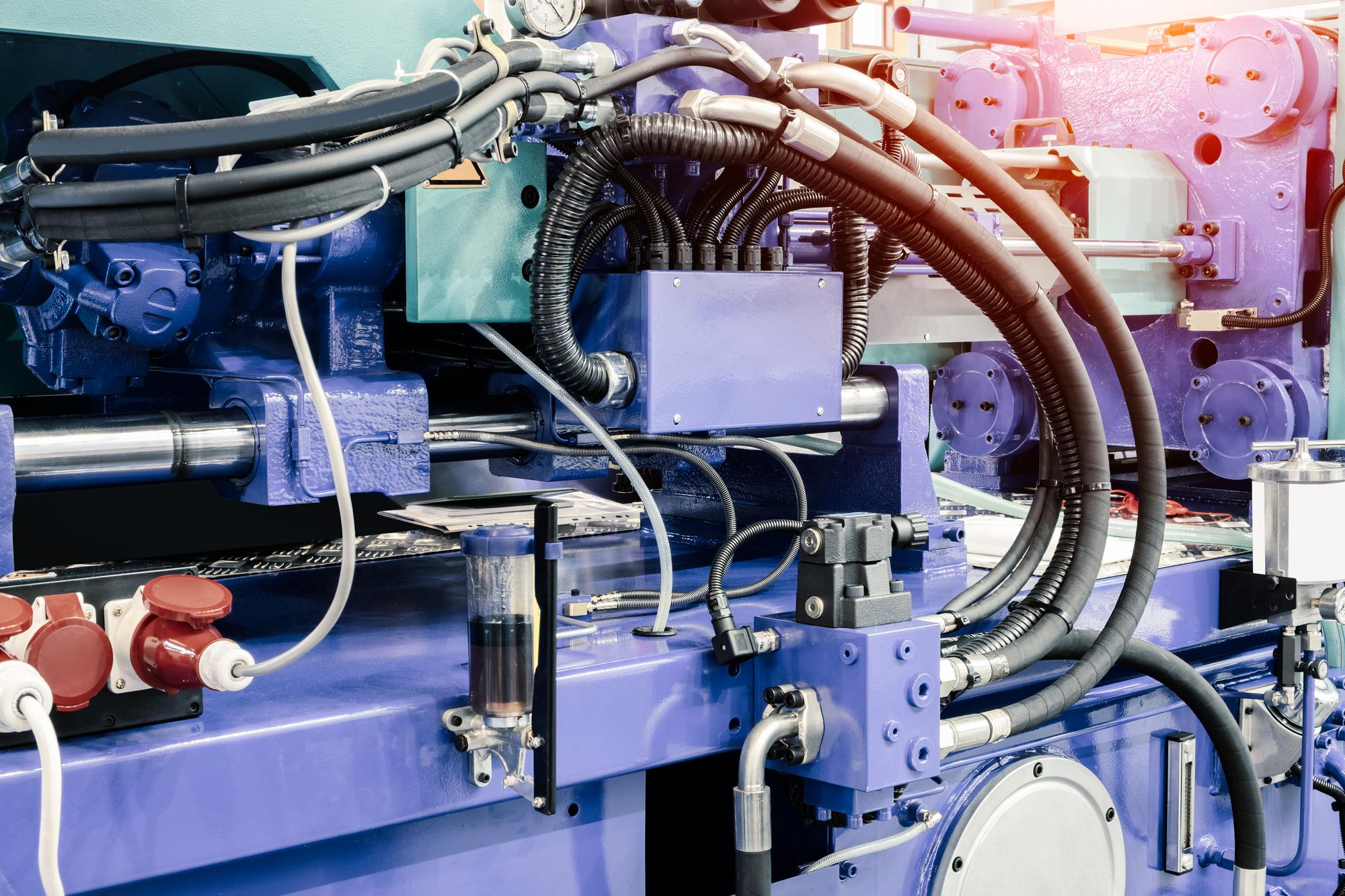

Plastic Injection(Plastic Injection Molding,又稱射出成型)是最常見的塑膠加工方式之一。透過加熱熔融塑膠顆粒,並將其注入金屬模具中冷卻成型,即可大量生產外觀一致、精度高的零件。

常見應用包含:

醫療器材(血糖機外殼、管件)

汽機車零件(電動機車定子件、車燈外殼)

3C產品(按鍵、外殼)

生活用品(廚房用品、衛浴配件)

二、塑膠射出流程解析

產品設計 – 客戶提供 2D/3D 圖面,需考慮外觀、強度、功能。

模具設計與製作 – 模具品質直接影響產品壽命與精度。

射出成型 – 將塑膠顆粒加熱至熔融狀態,注入模具成型。

冷卻與脫模 – 成品冷卻後自動或手動取出。

品管檢測 – 尺寸測試、外觀檢查、強度測試,確保符合標準。

三、塑膠射出常用材料

不同產品需求,需要選擇不同的塑膠材料:

ABS:韌性佳、適合外殼零件

PC(聚碳酸酯):透明度高,常用於燈罩、光學件

PP(聚丙烯):耐酸鹼、食品容器常見

POM:高強度、低摩擦,適合齒輪零件

PMMA(壓克力):高透明度,可做光學應用

四、選擇塑膠射出代工廠的重點

設備能力:是否具備多噸位射出機、能處理精密件。

模具技術:是否有模具設計、維修能力。

品質管理:是否有完整檢測流程,符合 ISO 或業界標準。

服務彈性:能否支援小量試產、大量量產。

案例經驗:是否有跨產業合作經驗(如醫療、電動機車、電子)。

五、家暘塑膠射出的優勢

完整服務鏈:從產品設計、模具開發、射出成型到組裝,一站式完成。

豐富經驗:參與多項電動機車、醫療設備與消費性產品的射出件製作。

多元材料處理:ABS、PC、PP、POM、PMMA 皆能加工。

品質保證:嚴格檢測流程,確保尺寸與外觀達到標準。

彈性生產:支援客戶從小量打樣到百萬件量產。

六、結論

塑膠射出是現代製造業不可或缺的加工方式,無論是醫療、交通、3C 或生活用品,都能透過精密射出成型快速量產,並兼顧品質與成本。

如果您正在尋找專業的塑膠射出代工廠,家暘將是您的可靠夥伴。

👉 立即聯絡我們,獲得專屬解決方案

The Plastic Injection Molding Process

Product Design – Customers provide 2D/3D drawings, considering appearance, strength, and functionality.

Mold Design & Fabrication – The quality of the mold directly affects product accuracy and durability.

Injection Molding – Plastic pellets are melted and injected into the mold cavity to form parts.

Cooling & Ejection – The molded part is cooled and then removed automatically or manually.

Quality Inspection – Dimensional measurement, visual inspection, and performance testing ensure compliance with requirements.

Common Plastic Materials for Injection Molding

Different products require different plastic materials:

ABS: Excellent toughness, suitable for housings and enclosures

PC (Polycarbonate): High transparency, ideal for lenses and lighting covers

PP (Polypropylene): Chemical-resistant, widely used for food containers

POM (Acetal): High strength and low friction, suitable for gears and mechanical parts

PMMA (Acrylic): High transparency, used in optical applications

How to Choose a Plastic Injection Molding Partner

Equipment Capability – Can the factory handle various tonnage machines and precision components?

Mold Expertise – Does it provide mold design, fabrication, and maintenance?

Quality Management – Are there strict inspection processes or ISO certifications?

Production Flexibility – Can it support both small-scale prototyping and high-volume production?

Industry Experience – Proven track record in medical, EV, electronics, and consumer products.

Advantages of Jiayang Plastic Injection Molding

One-Stop Service: From product design, mold development, injection molding, to assembly.

Extensive Experience: Participation in multiple EV, medical, and consumer product projects.

Material Expertise: Capable of processing ABS, PC, PP, POM, PMMA, and more.

Quality Assurance: Strict inspection processes to ensure accuracy and appearance.

Flexible Production: Supporting everything from low-volume trials to million-unit mass production.

Conclusion

Plastic injection molding is an essential process in modern manufacturing. Whether for medical devices, transportation, electronics, or household products, injection molding ensures fast mass production with consistent quality and cost efficiency.

If you are looking for a professional plastic injection molding manufacturer, Jiayang is your reliable partner.

👉 Contact us today for a tailored solution.